Quality Inspection for Stainless Steel Water Filter Cartridge - High Flow Melt Blown Filter Cartridge – Tianshan

Quality Inspection for Stainless Steel Water Filter Cartridge - High Flow Melt Blown Filter Cartridge – Tianshan Detail:

◆100% high purity polypropylene (melt blown), thermally bonded on a polypropylene centre core, no adhesives

◆High dirt holding capacity and low pressure loss

◆Many connections (DOE, 226 ,222 End caps) are available

◆Wide chemical compatibility, various micron ratings (1um to 100um)

◆One piece construction up to 1524mm (60”)

• Prefiltration in process water treatment industry;

• Clarification for waste water treatment;

• Bottled water, wine, beer pre-fltration in food& beverage industry

• Prefiltration before RO system in electronics process water,

• Organic solvents, inks, plating solution, metal cutting luids, photoresist filtration

Table : Typical water flow rate (10″)

| Materials Of Construction | Filter Media: | Melt Blown Polypropylene | ||||

| Micron Rating: | 1.0, 5.0, 10.0, 20, 50, 70, 100um | |||||

| Inner core: | Polypropylene or Coreless | |||||

| O-rings/gaskets(Only for 226, 222 Ends): | Silicone, Nitrile, EPDM, Viton, etc | |||||

| Filtration Efficiency | ≥80% | |||||

| Cartridge Dimensions | Outer Diameter | 63mm (2.5″) / 114mm (4.5″) | ||||

| Inner Diameter | 28mm (1.10″) | |||||

| Length(based on DOE end caps) | 10″- 254mm, 20″- 508mm, 30″-762 mm, 40″- 1016mm | |||||

| Filtration Area(m2) | 0.4 m2 per 10” | |||||

| Operating conditions | Normal Operating Temperature: | Up to 50℃ (122℉) | ||||

| Max.Operating Temperature.: | 80℃ (176℉) at △P≤1.0 bar (14psi) | |||||

| Max. Differential Pressure | ||||||

| Normal Flow direction: | 4.0 bar (58psi) at 25℃ (77℉) | |||||

| Reverse flow direction: | 2.0 bar (29psi) at 25℃ (77℉). | |||||

| PH Value compatibility: | 1-13 | |||||

| Sterilization: | Not recommended | |||||

| PRODUCT | MICRON | Outer DIA. | ADAPTER | LENGTH | O-RING / GASKET | |

| CP | 100-1um | D63-63mm(2.5″) | AA- CUT ENDS (NIL) | 10-10″ | S-silicone; N-nitrile | |

| 500-5um | D114-114mm(4.5″) | BN-222/ FIN | 20-20″ | E-epdm ; V- viton | ||

| 1000-10um | CN-226/ FIN | 30-30″ | ||||

| 2000-20um | 40-40″ | How to Order?- Example | ||||

| Other-XX | Micron:1um; Outer Dia:63mm; Adapter: NIL; Length: 10″ | |||||

| Selection Code is: CP100D63AA10 | ||||||

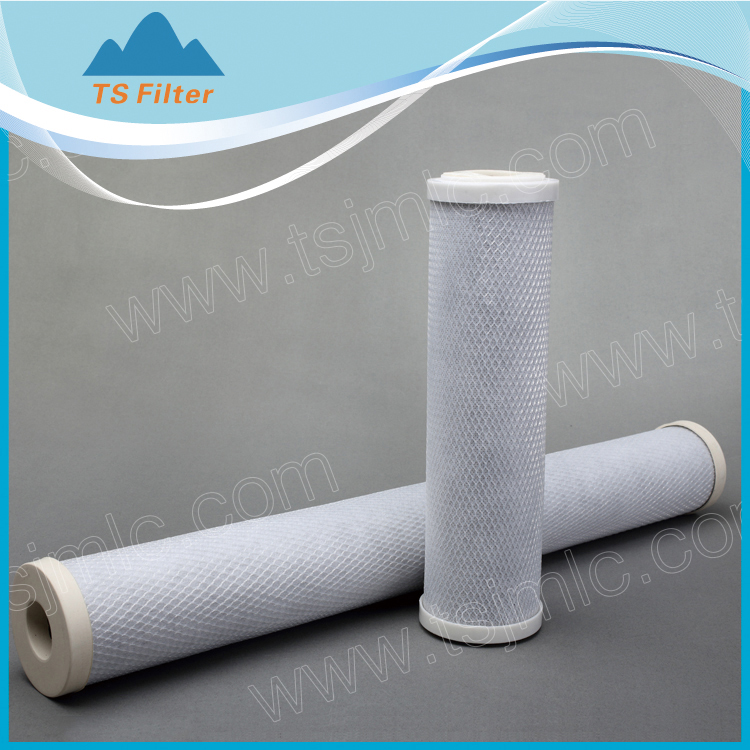

Product detail pictures:

Related Product Guide:

Our development depends on the advanced equipment, excellent talents and continuously strengthened technology forces for Quality Inspection for Stainless Steel Water Filter Cartridge - High Flow Melt Blown Filter Cartridge – Tianshan , The product will supply to all over the world, such as: Qatar, Paris, South Korea, we're now looking forward to even greater cooperation with overseas customers based on mutual benefits. We are going to work wholeheartedly to improve our products and services. We also promise to work jointly with business partners to elevate our cooperation to a higher level and share success together. Warmly welcome you to visit our factory sincerely.

It's really lucky to find such a professional and responsible manufacturer, the product quality is good and delivery is timely, very nice.

Write your message here and send it to us