The air used in the fermentation industry must be clean and sterile, and the air must have a certain pressure and suitable temperature and humidity for the growth of production bacteria, so as to ensure the normal growth of production bacteria in the fermenter. The so-called sterile air refers to the clean air in which the amount of bacteria in the air after sterilization is reduced to zero or the sterilization efficiency reaches ~ 199.9999%.

In ordinary cities, there are 3000~8000 bacteria /m in the air. If one bacterium enters the fermenting tank, there will be 10 bacteria after 15h of propagation, which will inevitably lead to serious interference or failure of fermentation production. Therefore, it is very necessary for fermentation enterprises to configure sterile air filters with optimized structure.

The sterile air filter used in the fermentation industry has experienced the transformation from low efficiency and high energy consumption to high efficiency and energy saving. When the total air filter, filter filter medium are cotton, activated carbon, called cotton carbon + cotton carbon filter; When the total empty filter, filter medium

For cotton, activated carbon and glass fiber, called cotton carbon + laminated plate filter; When the filter medium of the total empty filter and the filter is glass fiber and metal composite film, it is called glass fiber + metal film filter; When the filter medium of the total empty filter and the filter is glass fiber and polytetrafluoroethylene membrane, it is called folded membrane + polymer membrane filter.

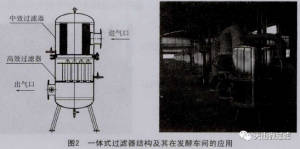

At present, most fermentation enterprises are still using the traditional split folded membrane air filter (hereinafter referred to as split filter), which accounts for more than 90% of the filter market in the fermentation industry. The split-type filter structure and its application in fermentation cart are shown in Figure 1.

With the continuous innovation and development of filter technology, the disadvantages of split filter increasingly appear, its structure design is unreasonable, medium effect filter can not be sterilized, occupy a large space, high cost of input defects, the enterprise’s energy, resources, manpower caused by a large waste. Enterprises are looking forward to the use of more reasonable structure design, cost-effective new filter products, to solve the actual problems in production.

1 integral folding membrane filter

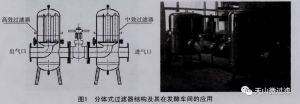

Integrated folded membrane filter (hereinafter referred to as integrated filter) is a sterile air filter designed to meet the needs of users. It combines the advantages of split filter and metal composite membrane filter in one, has the characteristics of compact structure, strong reliability and high cost performance. The integrated filter has been applied in dozens of enterprises in the fermentation industry, and hundreds of sets have been used, which have achieved good use results and been praised and recognized by users. The integrated filter structure and its application in the fermentation workshop are shown in Figure 2.

The integrated filter is composed of medium and high efficiency filters vertically connected up and down, which breaks the structure form of the split filter and changes from the split filter to the integrated filter. Compared with split-type filter, it has obvious advantages:

(1) From the overall structure, the design is novel and the structure is reasonable. Compared with the same flow split filter, its empty space can be saved by 1/2.

(2) From the fermentation process, can be the whole disinfection, strong reliability. Medium and high efficiency filters can be sterilized at the same time. 150 ℃.

(3) From the perspective of equipment investment, cost reduction, cost-effective. Compared with the price of the same flow split filter, the price can be reduced by about 1/3.

(4) From the point of prevention of bacterial infection, online monitoring can be realized to prevent the disease. The detected data can effectively prevent the occurrence of bacterial contamination accidents and ensure the normal fermentation production.

Post time: Oct-25-2022