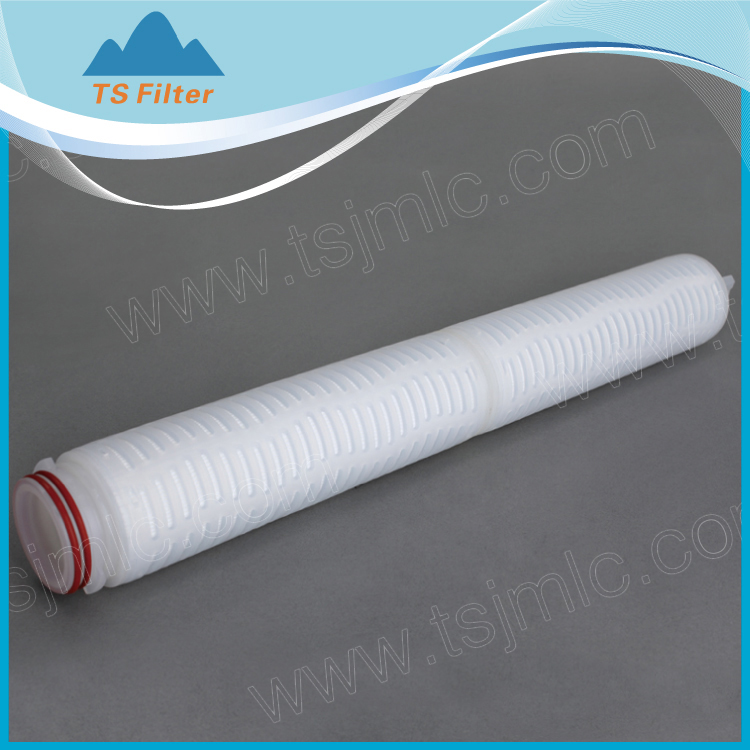

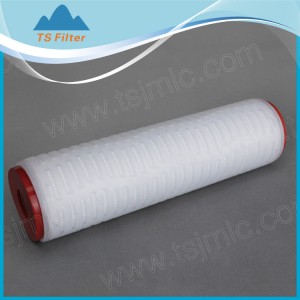

Manufacturer for TS Double Layers Hydrophilic PVDF Membrane Pleated Filter Cartridge for Pharmaceutical Industry

It really is our responsibility to satisfy your requirements and competently serve you. Your fulfillment is our greatest reward. We’re on the lookout forward in your go to for joint progress for Manufacturer for TS Double Layers Hydrophilic PVDF Membrane Pleated Filter Cartridge for Pharmaceutical Industry, Our organization has been devoting that “customer first” and committed to helping consumers expand their organization, so that they become the Big Boss !

It really is our responsibility to satisfy your requirements and competently serve you. Your fulfillment is our greatest reward. We’re on the lookout forward in your go to for joint progress for TS Made PVDF liquid filter cartridge, Our company always concentrate on the development of the international market. We’ve got a lot of customers in Russia , European countries, the USA, the Middle East countries and Africa countries. We always follow that quality is foundation while service is guarantee to meet all customers.

◆Hydrophilic PVDF Membrane filter for liquids sterile filtration, Absolute rating ≥99.99%

◆Low protein binding and low extractables, ideal for bioburden reduction and particle removal

◆High throughput flow rate with minimal differential pressure

◆Broad chemical compatibility, suitable for aggressive liquids and high viscosity liquids

◆Withstand multiple steam sterilization

◆Replace Sartorius ,Pall or Millipore Filter is available

•Ophthalmics, WFl;

•Diagnostics, diluents, serum, tissue culture media and media additives;

•Sterile filtration of high viscosity liquid

•Strong alkaline, acids and corrosive solvents;

Table : Typical water flow rate (10″)

| Materials Of Construction | Filter Media: | Hydrophilic PVDF Membrane | ||||

| Support Layers: | Polypropylene | |||||

| Micron Rating: | 0.1, 0.2, 0.45, 0.65, 1.0, 3.0 um | |||||

| Inner core: | Reinforced Polypropylene | |||||

| Outer Cage, End caps: | Reinforced Polypropylene | |||||

| Seal Method: | Thermal Bonded, No Adhesives | |||||

| O-rings/gaskets: | Silicone, Nitrile, EPDM, Viton, Teflon, etc | |||||

| Cartridge Dimensions | Outer Diameter | 69mm(2.75”) | ||||

| Inner Diameter | 33mm(1.30”) | |||||

| Length(based on DOE end caps) | 10″- 254mm, 20″- 508mm, 30″-762 mm, 40″- 1016mm | |||||

| Filtration Area(m2) | 0.65 m2 per 10” | |||||

| Operating conditions | Normal Operating Temperature: | Up to 65℃ (140℉) | ||||

| Max.Operating Temperature.: | 90℃ (194℉) at △P≤1.0 bar (14psi) | |||||

| Max. Differential Pressure | ||||||

| Normal Flow direction: | 4.2 bar (60 psi) at 25℃ (77℉) | |||||

| Reverse flow direction: | 2.1 bar (30psi) at 25℃ (77℉). | |||||

| PH Value compatibility: | 1-13 | |||||

| Sterilization: | Steam Sterilization for 30 minutes at 135℃(275℉) Cumulative Time: 50hours |

|||||

| Cartridge Safety | Endotoxin: | <0.25 EU/ml | ||||

| Extractables: | 0.03g / 10″ | |||||

| GRADE | PRODUCT | MICRON | ADAPTER | LENGTH | O-RING / GASKET | |

| F - FOOD & BEVERAGE | DHPV | 020-0.2um | AA- DOE | 10-10″ | S-silicone; N-nitrile | |

| P - PHARMACEUTICAL | 045-0.45um | CN-226/FIN | 20-20″ | E-epdm ; T-teflon (encaptulated) | ||

| C - CHEMICAL | 080-0.8um | BN-222/FIN | 30-30″ | V-viton | ||

| E - ELECTRICAL | 100-1.0um | BF-222/ FLAT SEAL | 40-40″ | How to Order?- Example | ||

| CF-226/FLAT SEAL | 05-5″ | Pharmaceutical grade; Micron:0.45um; Length:10″ ADAPTER: DOE; Gakset: Silicone. Selection Code is: PDHPV045AA10S | ||||

| EN-222 three locking ears /Fin | Other-XX | |||||

It really is our responsibility to satisfy your requirements and competently serve you. Your fulfillment is our greatest reward. We’re on the lookout forward in your go to for joint progress for Manufacturer for TS Double Layers Hydrophilic PVDF Membrane Pleated Filter Cartridge for Pharmaceutical Industry, Our organization has been devoting that “customer first” and committed to helping consumers expand their organization, so that they become the Big Boss !

Manufacturer for , Our company always concentrate on the development of the international market. We’ve got a lot of customers in Russia , European countries, the USA, the Middle East countries and Africa countries. We always follow that quality is foundation while service is guarantee to meet all customers.