Factory source Sintered Filter Element - Junior Pleated Membrane Filter Cartridge – Tianshan

Factory source Sintered Filter Element - Junior Pleated Membrane Filter Cartridge – Tianshan Detail:

◆Wide range of filter medias to meet various process systems PP, PES, PTFE, NYLON66, PVDF for options.

◆Ideal for small and medium batch processing prefiltration and sterile filtration in air and liquids

◆Removal rating from 0.1um to 50um for different filtration requirements

◆Two connections are available

214-Single Open End with one internal O-ring

Pall junior and Sartorius Mini filters replacement

216-Single Open End with two locking ears and two external O-rings

• Small-scale sterile process gases, sterile vents;

• Small and medium batch pharmaceuticals and bioprocessing

• Laboratory solutions;

• Electronics and semiconductors;

• Filtration for optical resin gum;

• Small-scale fine chemicals and solvents;

• Point-of-use water supply

| Materials Of Construction | Filter Media: | PES/PP/PTFE/NYLON66/PVDF | ||||

| Support Layers: | Polypropylene | |||||

| Inner core: | Polypropylene/SUS | |||||

| Outer Cage, End caps: | Polypropylene | |||||

| Seal Method: | Thermal Bonded, No Adhesives | |||||

| O-rings/gaskets: | Silicone, Nitrile, EPDM, Viton, etc | |||||

| Cartridge Dimensions | Outer Diameter | 56mm | ||||

| Length | 70mm (Except End Cap) 125mm(Except End Cap) |

|||||

| Filtration Area(m2) | 0.12 m2(70mm length) 0.23 m2(132mm length) |

|||||

| Operating conditions | Normal Operating Temperature: | Up to 60℃ (140℉) | ||||

| Max.Operating Temperature.: | 80℃ (176℉) at △P≤1.0 bar (14psi) | |||||

| Max. Differential Pressure | ||||||

| Normal Flow direction: | 4.2 bar (60 psi) at 25℃ (77℉) | |||||

| Reverse flow direction: | 2.1 bar (30psi) at 25℃ (77℉). | |||||

| PH Value compatibility: | 6-14 | |||||

| Sterilization: | Steam Sterilization for 30 minutes at 135℃(275℉) | |||||

| Cartridge Safety | Endotoxin: | <0.25 EU/ml | ||||

| Extractables: | 0.03g / 10″ | |||||

| GRADE | TYPE | FILTER MEDIA | MICRON | ADAPTER | LENGTH | O-RING / GASKET | |

| P- PHARMACEUTICAL | XF | IPS | 010-0.1um | 214 | 1-70mm | S-silicone; N-nitrile | |

| F-FOOD | DPP | 020-0.2um | 216 | 2-125mm | E-epdm ; V-Viton | ||

| E-ELECTRONIC | IPF | 045-0.45um | |||||

| DPNN | 065-0.65um | How to Order?- Example | |||||

| DHPV | 100-1um | Pharmaceutical grade; Filter Media:PES; Micron:0.1um; Length:70mm; ADAPTER: 214; O-ring: Silicone. Selection Code is: PXFIPS0102141S | |||||

| 500-5um | |||||||

| 1000-1um | |||||||

| 5000-5um | |||||||

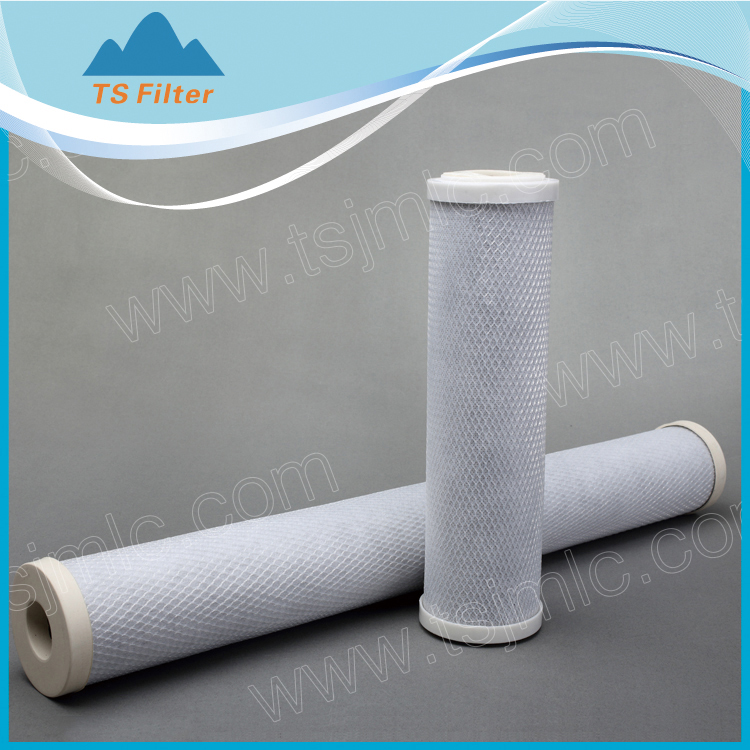

Product detail pictures:

Related Product Guide:

Our business aims to operating faithfully, serving to all of our clients , and working in new technology and new machine continuously for Factory source Sintered Filter Element - Junior Pleated Membrane Filter Cartridge – Tianshan , The product will supply to all over the world, such as: India, Indonesia, Netherlands, Our team knows well the market demands in different countries, and is capable of supplying suitable quality products and solutions at the best prices to different markets. Our company has already set up a experienced, creative and responsible team to develop clients with the multi-win principle.

High production efficiency and good product quality, fast delivery and completed after-sale protection, a right choice, a best choice.

Write your message here and send it to us