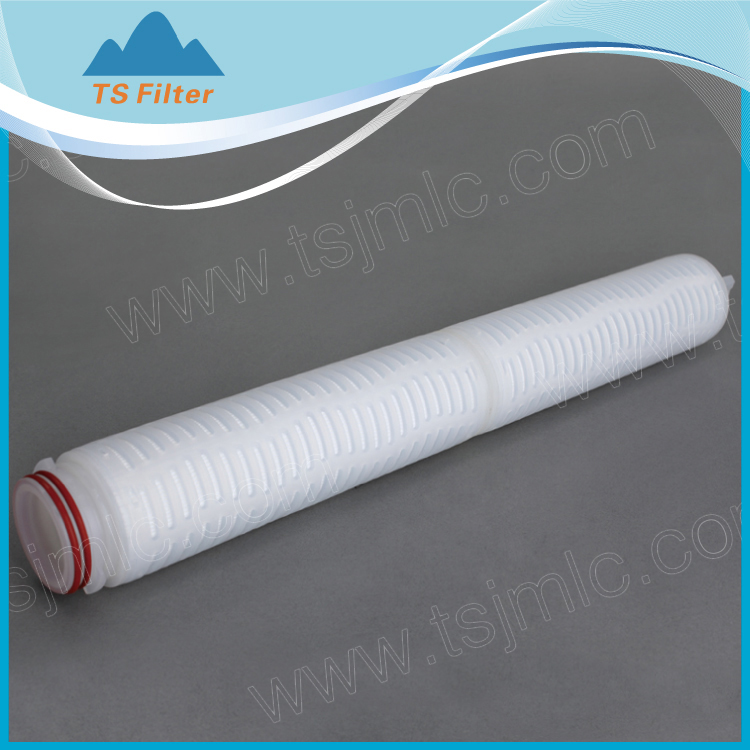

factory low price 10 Micron Stainless Steel Pleated Filter Cartridge - High Flow Melt Blown Filter Cartridge – Tianshan

factory low price 10 Micron Stainless Steel Pleated Filter Cartridge - High Flow Melt Blown Filter Cartridge – Tianshan Detail:

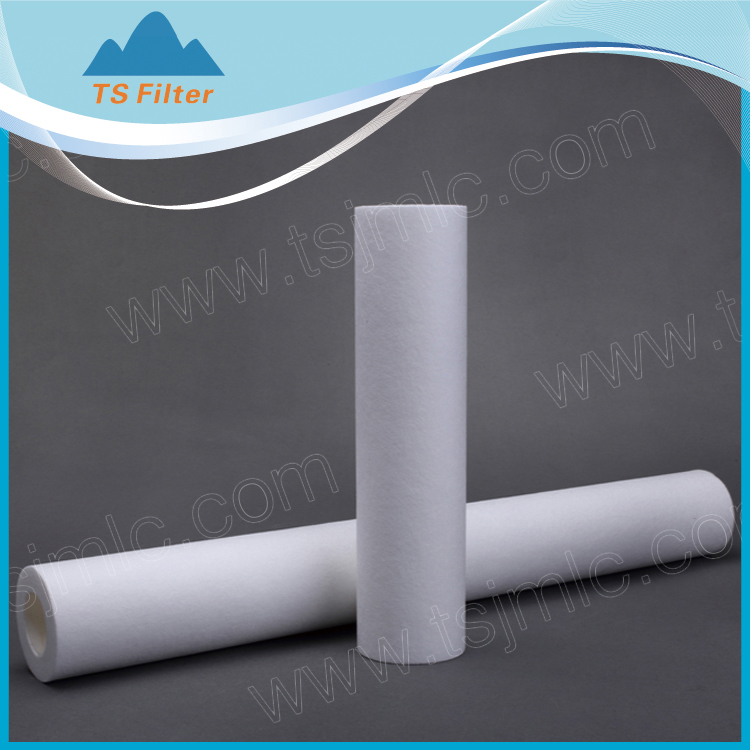

◆100% high purity polypropylene (melt blown), thermally bonded on a polypropylene centre core, no adhesives

◆High dirt holding capacity and low pressure loss

◆Many connections (DOE, 226 ,222 End caps) are available

◆Wide chemical compatibility, various micron ratings (1um to 100um)

◆One piece construction up to 1524mm (60”)

• Prefiltration in process water treatment industry;

• Clarification for waste water treatment;

• Bottled water, wine, beer pre-fltration in food& beverage industry

• Prefiltration before RO system in electronics process water,

• Organic solvents, inks, plating solution, metal cutting luids, photoresist filtration

Table : Typical water flow rate (10″)

| Materials Of Construction | Filter Media: | Melt Blown Polypropylene | ||||

| Micron Rating: | 1.0, 5.0, 10.0, 20, 50, 70, 100um | |||||

| Inner core: | Polypropylene or Coreless | |||||

| O-rings/gaskets(Only for 226, 222 Ends): | Silicone, Nitrile, EPDM, Viton, etc | |||||

| Filtration Efficiency | ≥80% | |||||

| Cartridge Dimensions | Outer Diameter | 63mm (2.5″) / 114mm (4.5″) | ||||

| Inner Diameter | 28mm (1.10″) | |||||

| Length(based on DOE end caps) | 10″- 254mm, 20″- 508mm, 30″-762 mm, 40″- 1016mm | |||||

| Filtration Area(m2) | 0.4 m2 per 10” | |||||

| Operating conditions | Normal Operating Temperature: | Up to 50℃ (122℉) | ||||

| Max.Operating Temperature.: | 80℃ (176℉) at △P≤1.0 bar (14psi) | |||||

| Max. Differential Pressure | ||||||

| Normal Flow direction: | 4.0 bar (58psi) at 25℃ (77℉) | |||||

| Reverse flow direction: | 2.0 bar (29psi) at 25℃ (77℉). | |||||

| PH Value compatibility: | 1-13 | |||||

| Sterilization: | Not recommended | |||||

| PRODUCT | MICRON | Outer DIA. | ADAPTER | LENGTH | O-RING / GASKET | |

| CP | 100-1um | D63-63mm(2.5″) | AA- CUT ENDS (NIL) | 10-10″ | S-silicone; N-nitrile | |

| 500-5um | D114-114mm(4.5″) | BN-222/ FIN | 20-20″ | E-epdm ; V- viton | ||

| 1000-10um | CN-226/ FIN | 30-30″ | ||||

| 2000-20um | 40-40″ | How to Order?- Example | ||||

| Other-XX | Micron:1um; Outer Dia:63mm; Adapter: NIL; Length: 10″ | |||||

| Selection Code is: CP100D63AA10 | ||||||

Product detail pictures:

Related Product Guide:

Our mission should be to turn out to be an innovative supplier of high-tech digital and communication devices by furnishing benefit added design and style, world-class manufacturing, and repair capabilities for factory low price 10 Micron Stainless Steel Pleated Filter Cartridge - High Flow Melt Blown Filter Cartridge – Tianshan , The product will supply to all over the world, such as: Zambia, Liberia, Lithuania, The design, processing, purchasing, inspection, storage, assembling process are all in scientific and effective documentary process , increasing usage level and reliability of our brand deeply, which makes us become superior supplier of the four major product categories shell castings domestically and obtained the customer's trust well.

As an international trading company, we have numerous partners, but about your company, I just want to say, you are really good, wide range, good quality, reasonable prices, warm and thoughtful service, advanced technology and equipment and workers have professional training, feedback and product update is timely, in short, this is a very pleasant cooperation, and we look forward to the next cooperation!

Write your message here and send it to us